Steve Lawrence, principle at Macdonald & Lawrence, was the featured presenter on Sunday. Steve took 5 projects that he has been involved in and covered planning, philosophy, and practice related to logistics, hand raising lifts, scheduling and budgets, crew management, public participation, and other aspects of site work.

Macdonald and Lawrence has executed some quite large projects, in one case requiring 500 hours of pre-planning. One salient point Steve made early on was that the purpose of any planning is to increase safety and decrease cost, and wether the project is a 12×16 frame or a 30,000 sqft building, planning and its effect scale proportionally.

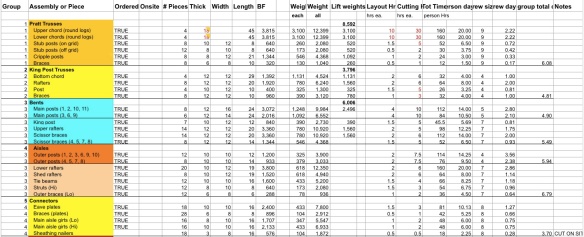

Steve showed how his initial timber list morphs into a powerful tool that can provide information for shipping, site planning, and a host of other phases of a project.

Excel sheet organizing the Pemberton Downtown Barn timber from mill order to cutting and raising time

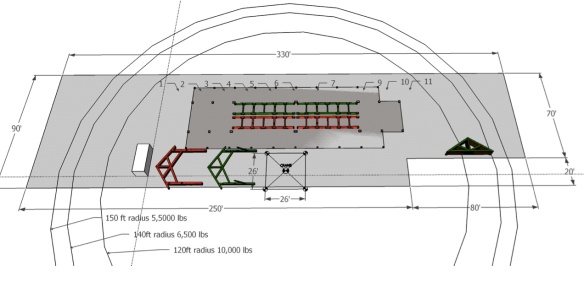

Using sketchup to provide animations of raising scripts can be a powerful tool for communicating a plan to a crew, and could even help to win a bid in a competitive environment.

Site plan for the Pemberton Downtown Barn showing crane lcoation and radius, pre-assembly staging, and building foortprint.

Placement of material on site at M&L is streamlined through the same excel document that was sent to the mill, making it simple to track material through the shop, on to the truck (or helicopter), to site, and in to final placement. If the enemy is shrinkage, material handling is its henchman.

Pre-assembly organized and ready.